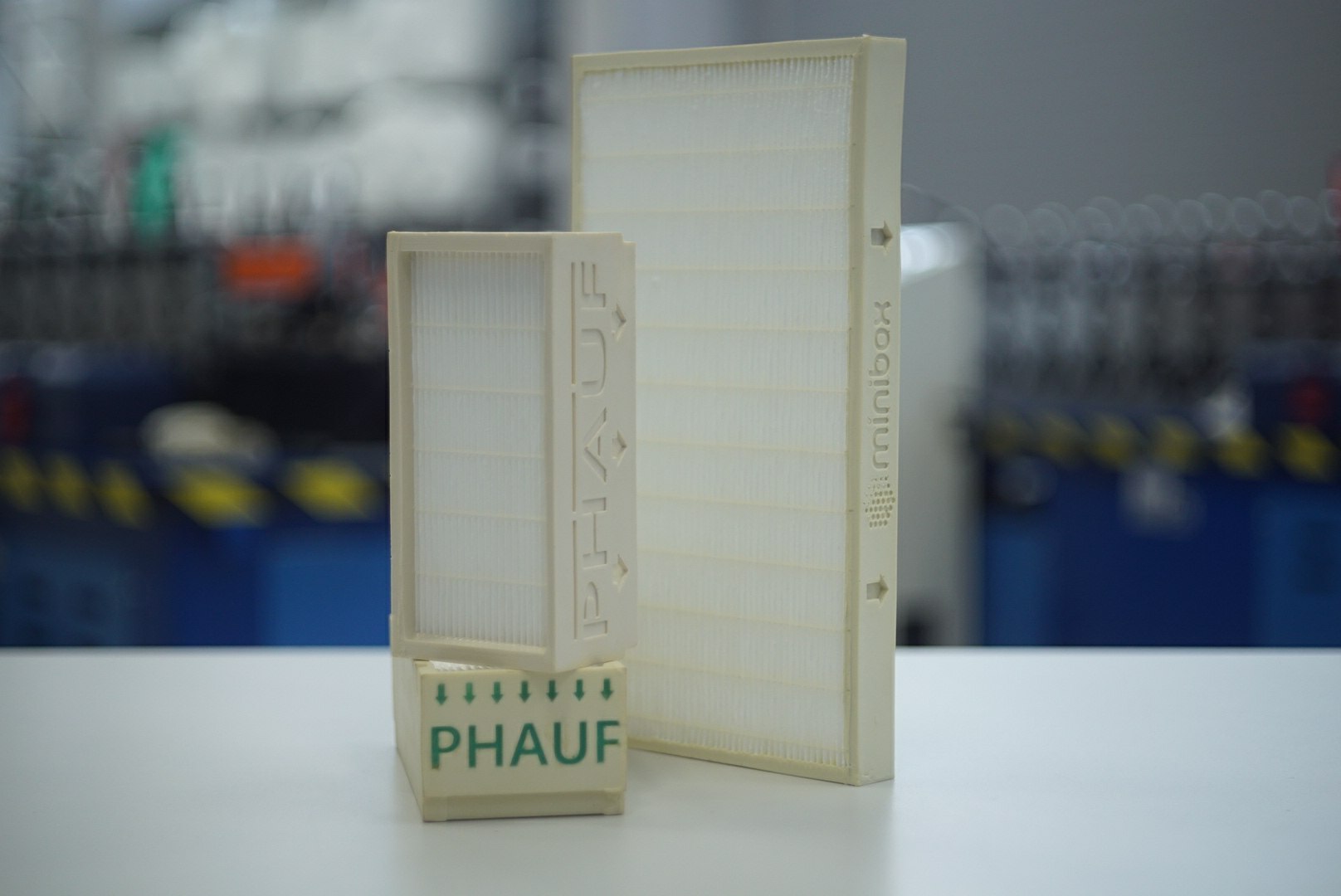

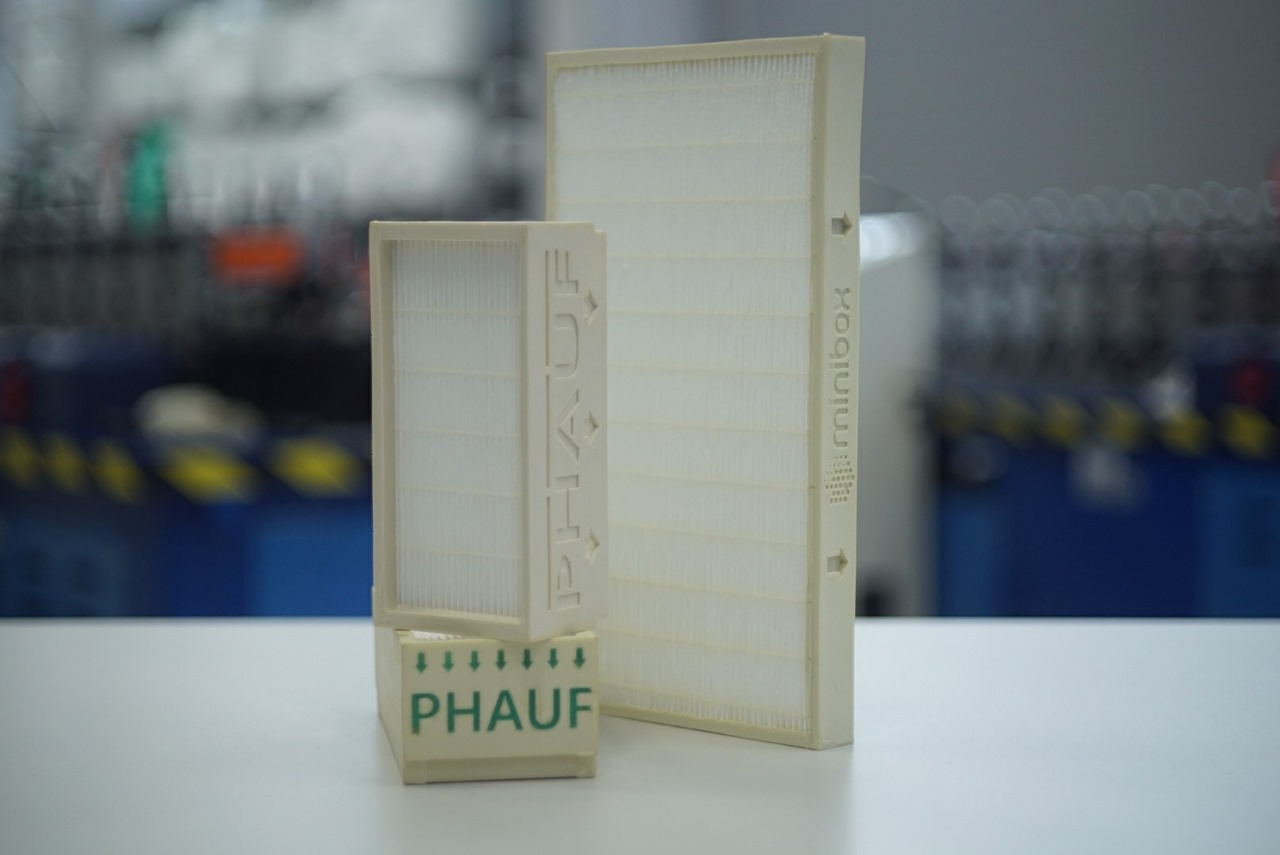

PRODUCTION

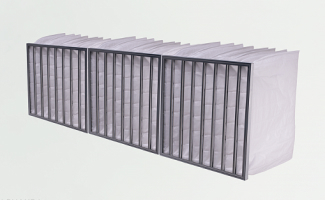

OF HIGH-EFFICIENCY

HEPA AND ULPA

AIR FILTERS

PRODUCTS

APPLICATIONS

Special environment in microelectronics is one of the most important criteria for producing quality products. The percentage of yield, a crucial indicator of crystal production quality, depends on the dust levels in rooms where deposition, diffusion, etching, and other processes occur. The air purification level in crystal production has the highest standard, with the cleanrooms of these productions using filters of the highest classes U16 and U17. Providing sensitive, advanced production processes and technologies with high-efficiency filters is the main focus of PHAUF’s activities.

Ensuring bacteriological air purity: Ensuring bacteriological air purity using the «Zero discharge» technology, antibacterial sealant, and anodized aluminum frame (eliminating the risk of oxidized aluminum particles entering the cleanroom), thereby achieving:

Production of beverages and food products in accordance with sanitary standards:

- prevention of microorganism contamination;

- prevention of excess moisture and condensation.

Daily protection of human health:

- control of household dust and allergen concentration in premises;

- reduction of the health impact of fine polluting particles;

- elimination of unpleasant odors.

THROUGHOUT RUSSIA

AND EAEU COUNTRIES

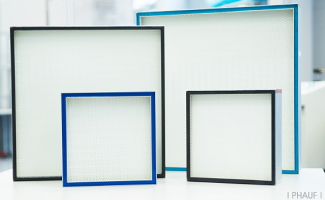

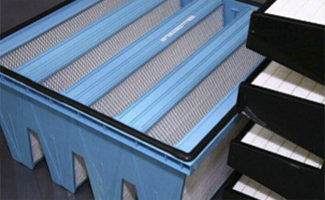

Our high-tech, robotic production is located in the Special Economic Zone «Istok», and was initially oriented towards foreign consumers, for whom high filter quality, confirmed by tests (ISO 16890, EN 977, EN 1822), is the most important factor in choosing partners.

The level of our technologies, the most modern equipment from leading manufacturers, as well as the range of products we produce, allow us to fully replace imported products from companies such as: TROX, AAF, CAMFIL, MIKROPOR, MEGE, VOLZ, FREUDENBERG, EMW, GENERAL FILTER, FCR, FILTAIR, ULPATEK, and in some cases even surpass them in quality.

ORDER FORM