Pocket filters (PF Series)

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 360 | 360 | 600 | 600 |

| Filter surface area, m² |

1.24 | 2.55 | 2.0 | 4.26 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

ORDER FORM

INFORMATION

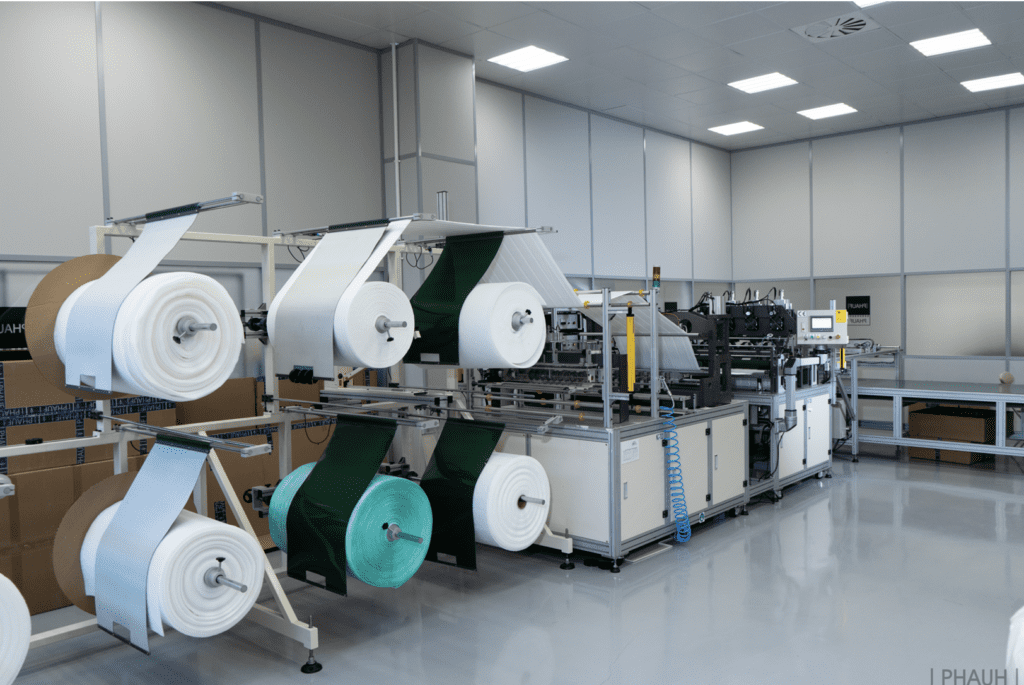

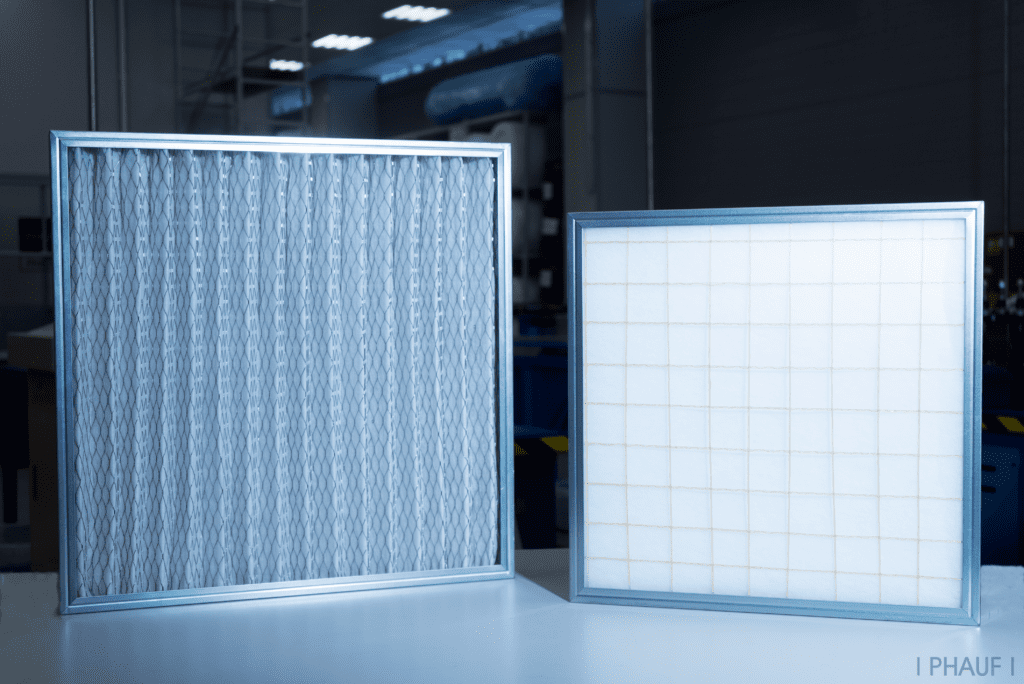

Pocket type air filters are manufactured for coarse, medium, and fine filtration (coarse filtration from G3-G4 class, medium filtration from M5-M6, fine from F7-F9). For coarse filtration, volumetric materials made of 100% polyester are used, while for fine filtration, polypropylene-based material using the «meltblown» technology is used.

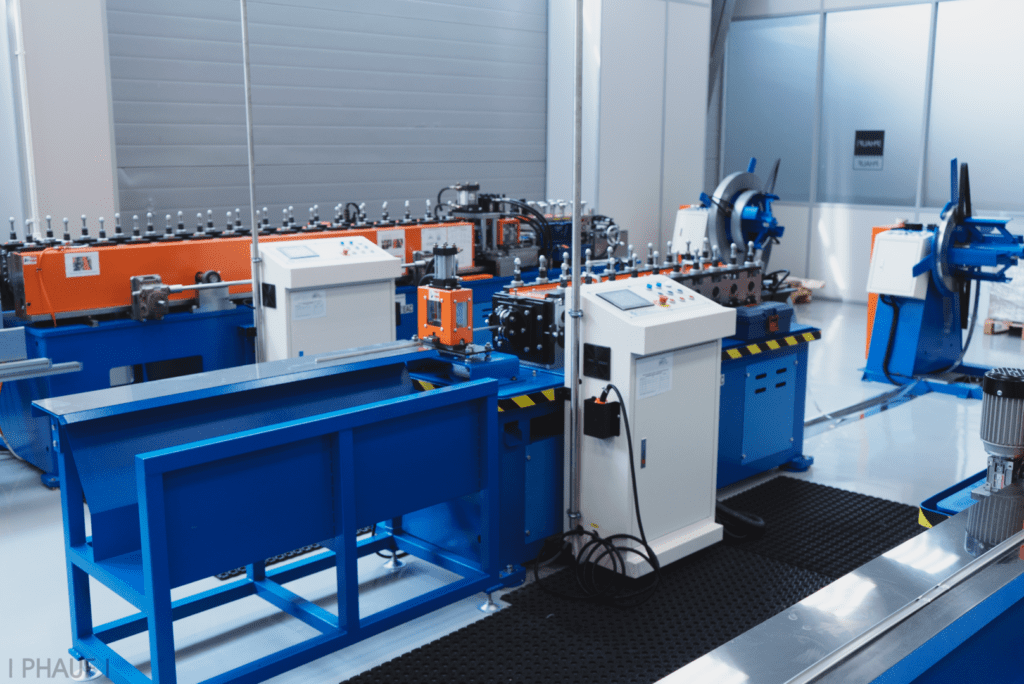

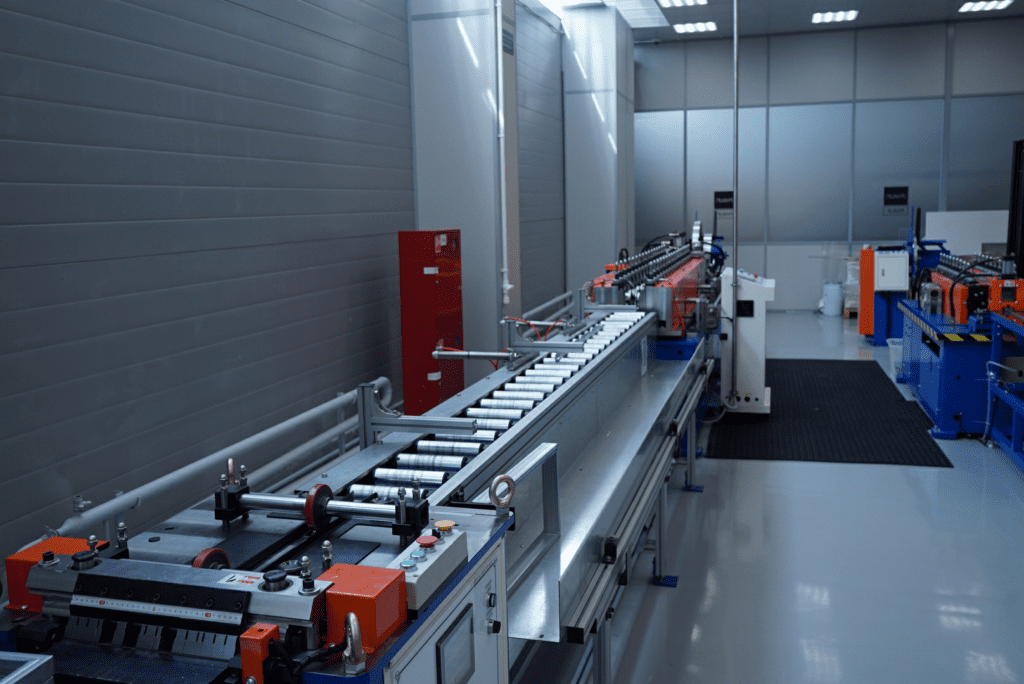

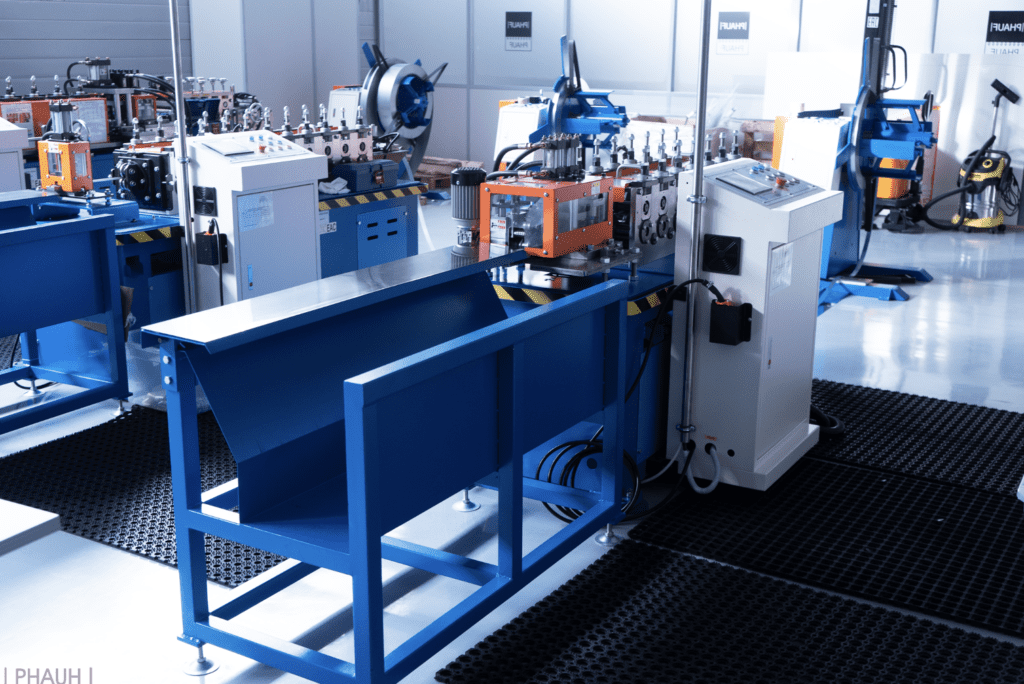

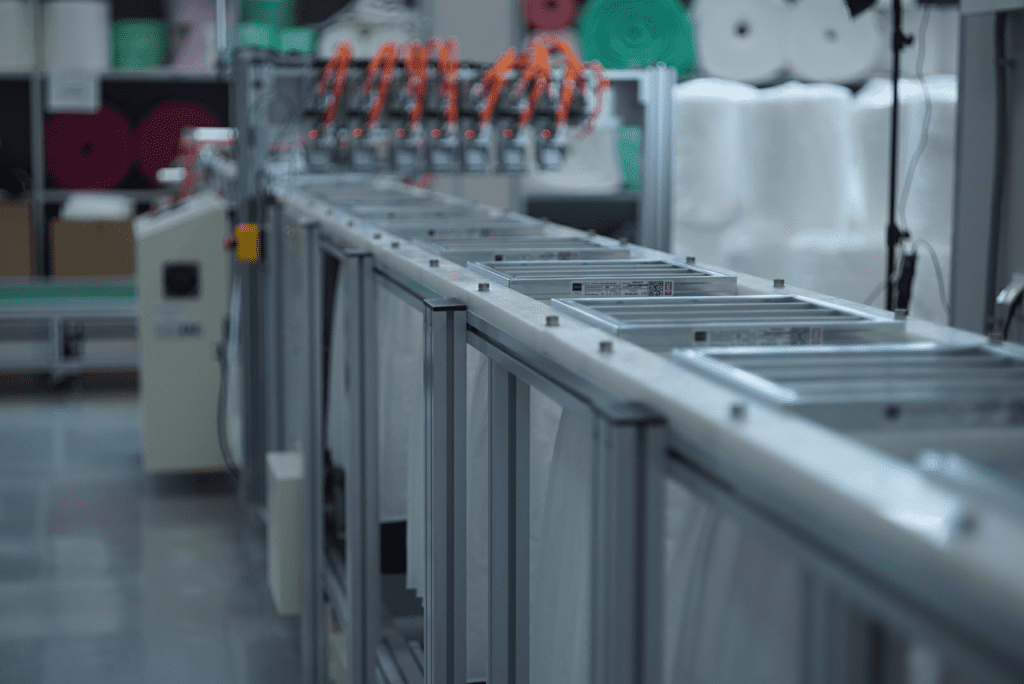

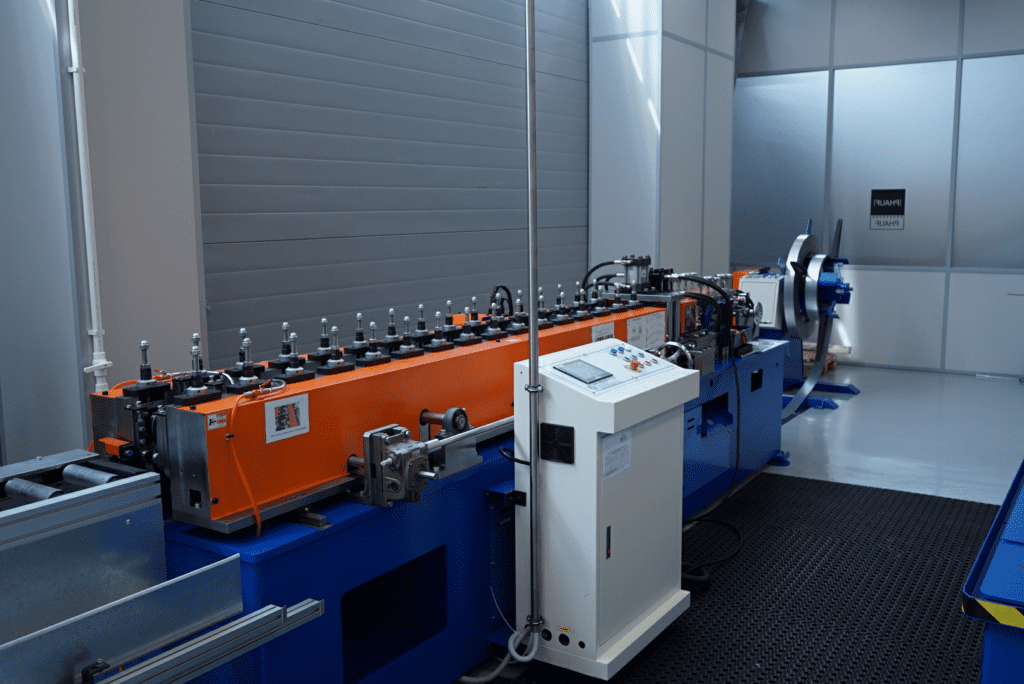

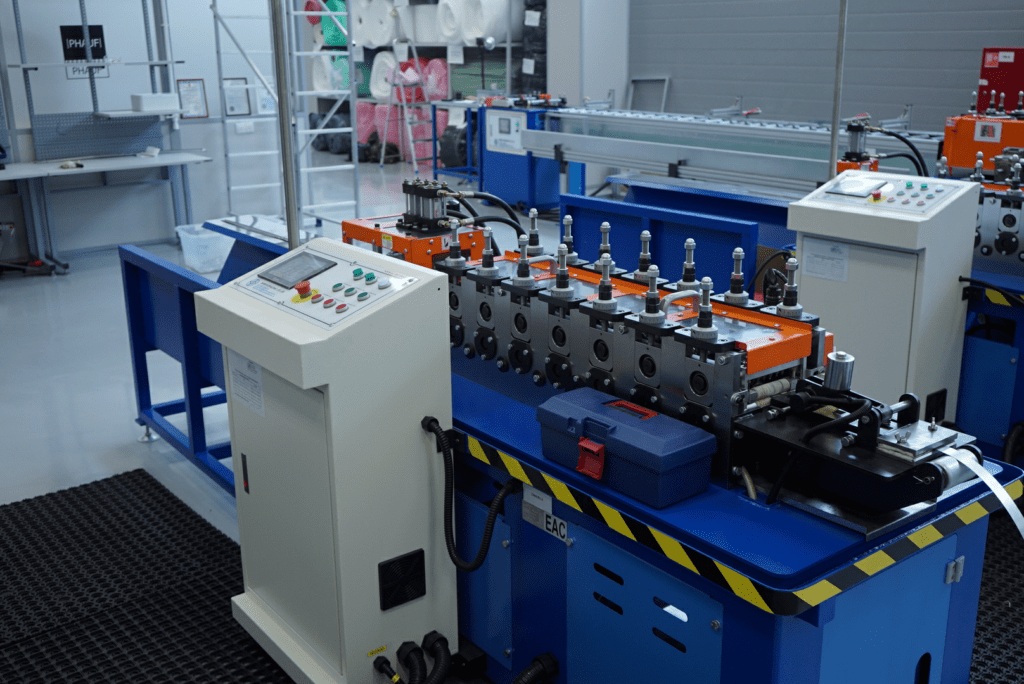

The filters are manufactured entirely on rolled profiles made of galvanized steel, without the use of adhesive compounds.

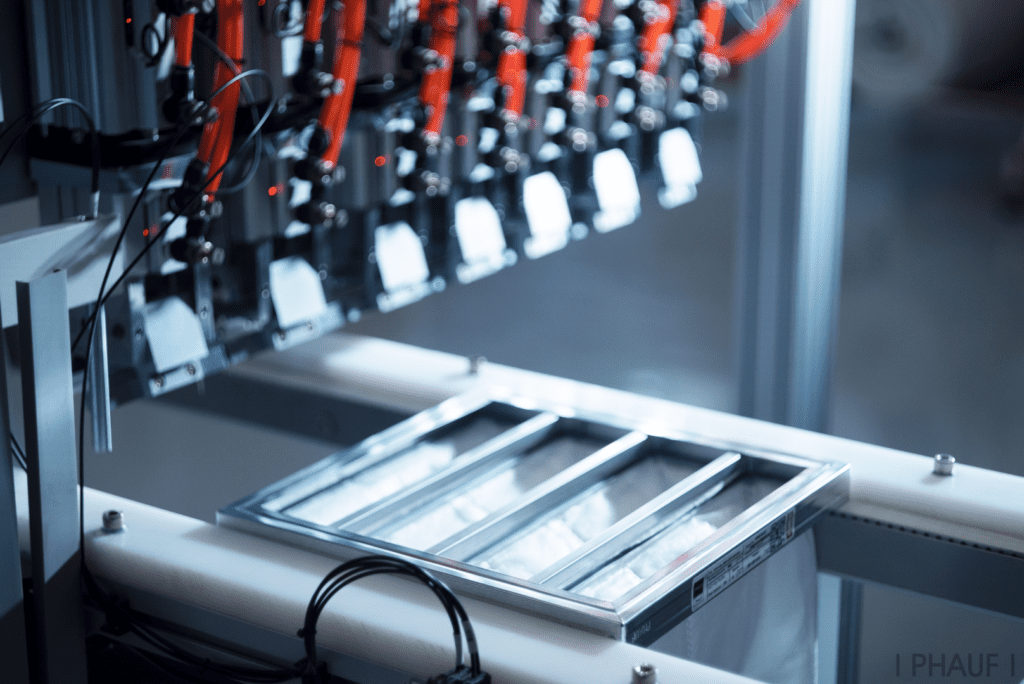

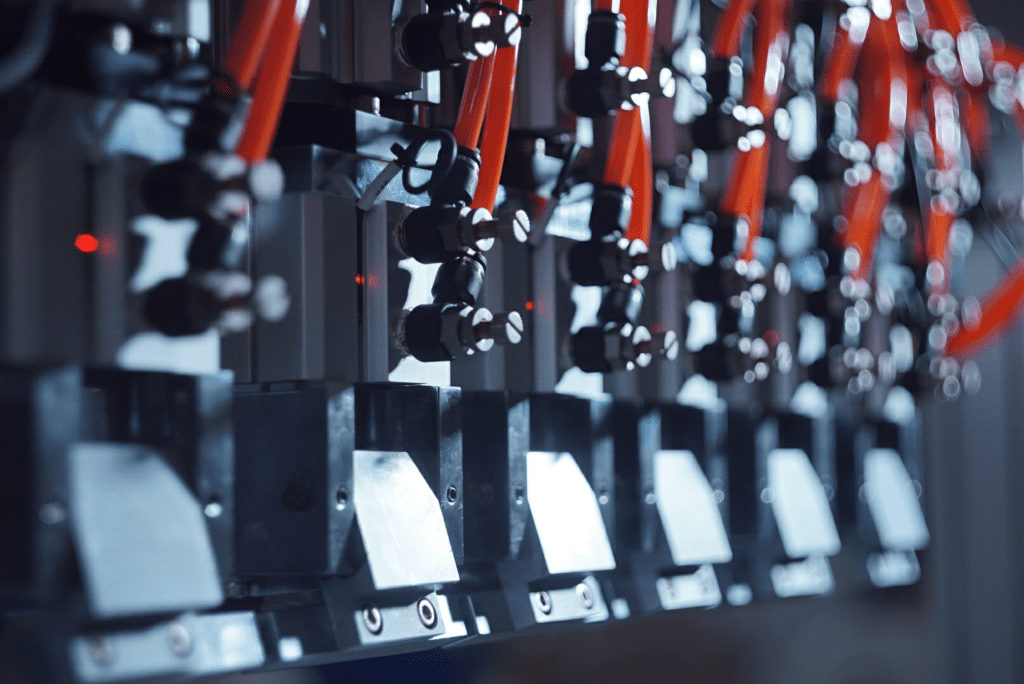

The attachment of filter pockets to the main frame is reliably achieved through a folded connection of the inner frame with the upper clamping guide (clip) on a fully automated line, without human intervention.

Each batch of filter media is tested on an ALF 114 tester (TOPAS, GmbH) to confirm parameters (initial pressure drop, efficiency, etc.) in accordance with Interstate Standard R EN 779 – 2014. At the customer’s request, we have the technical capability to conduct testing according to the new European standard ISO 16890.

The pockets are welded on a specialized ultrasonic line, which guarantees the accuracy of geometric dimensions, reliable seam connection, and ultimately, the quality of the entire product.

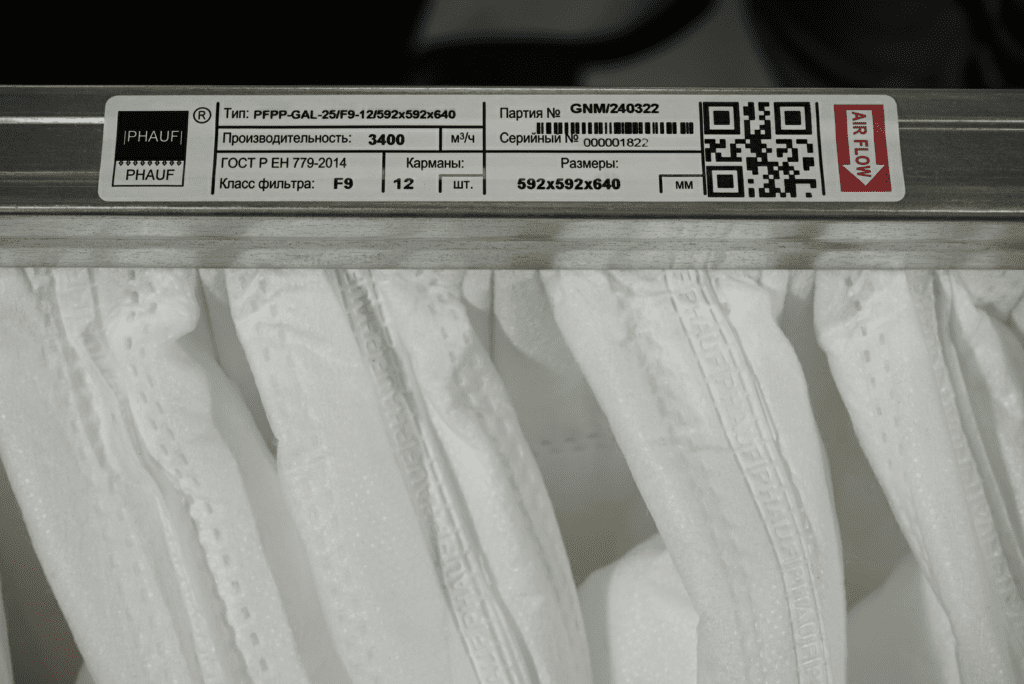

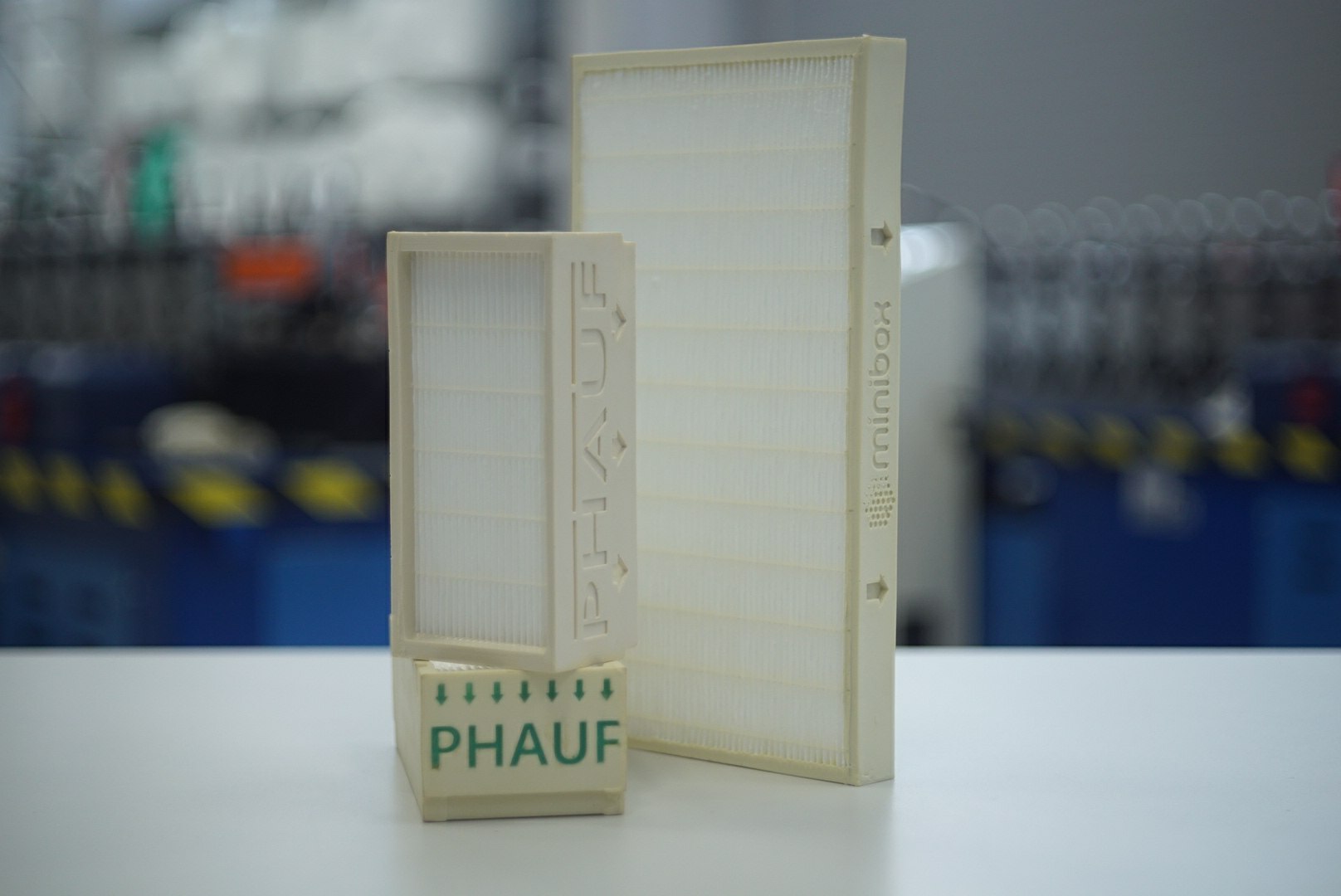

The filter consists of a main frame, internal frames equal to the number of pockets, filter pockets (their number depending on the filter size), and a sealant (optional). The main parameters of the filter are displayed on the label.

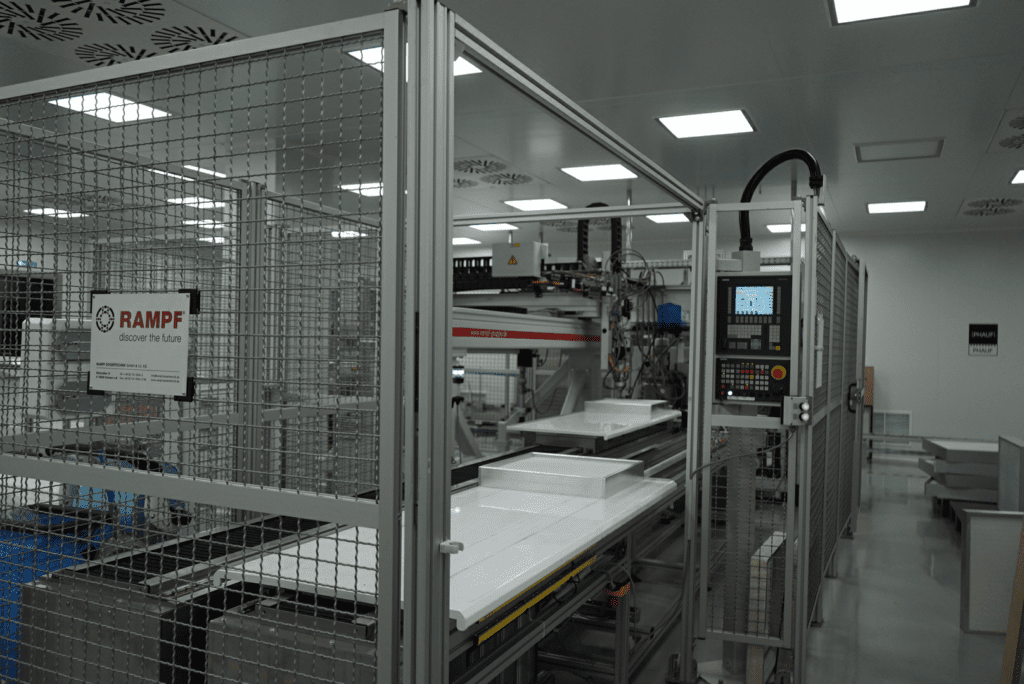

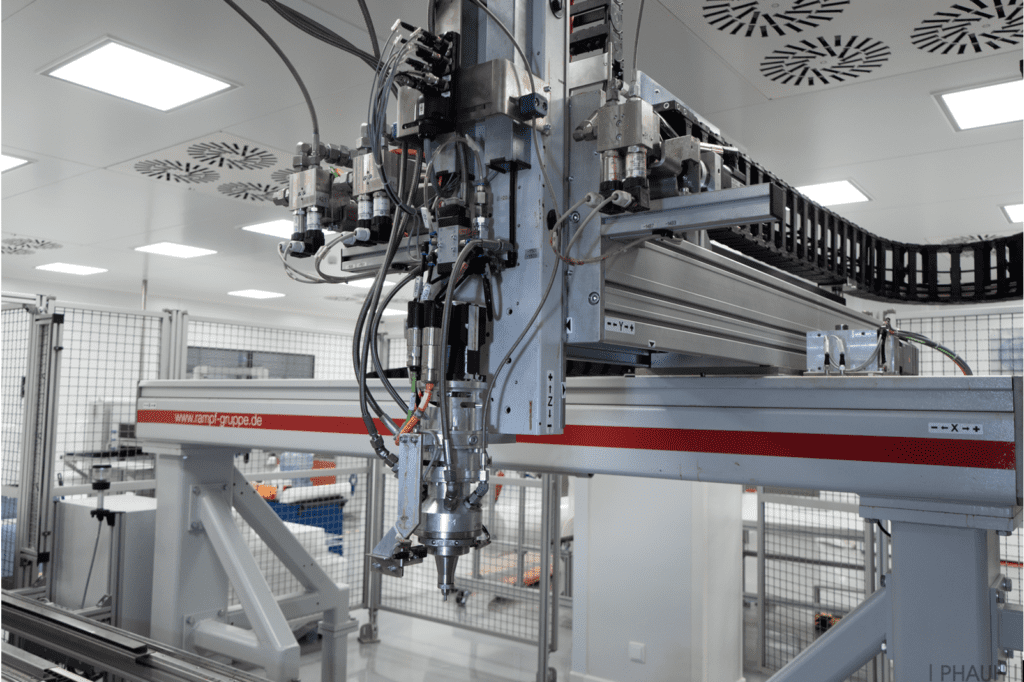

A seamless foamed polyurethane applied by adhesion on an automated DR-CNC complex (RAMPF, GmbH) or an adhesive-based sealant made of EPDM rubber is used as a sealant.

The finished products are specially packaged in group packaging, with all accompanying documents.

Coarse pocket filter with polyester material

| Filter Type Code | Size (H x W x D), mm | Number of pockets, pcs. | Filtration class Interstate Standard R EN 779-2014 | Nominal capacity, m3/h | Initial pressure drop, Pa | Filter surface area, m2 | Weight, kg |

| PFPE | 592х287х360 | 6 | G3 | 1700 | 40 | 1,24 | 1,2 |

| 592х592х360 | 3400 | 40 | 2,55 | 1,9 | |||

| 592х592х600 | 1700 | 35 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 35 | 4,26 | 2,2 | |||

| 592х287х360 | G4 | 1700 | 45 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 45 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 40 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 40 | 4,26 | 2,2 | |||

| 592х287х360 | M5 | 1700 | 55 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 55 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 50 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 50 | 4,26 | 2,2 |

Fine pocket filter with meltblown material

| Filter Type Code | Size (H x W x D), mm | Number of pockets, pcs. | Filtration class Interstate Standard R EN 779-2014 | Nominal capacity, m3/h | Initial pressure drop, Pa | Filter surface area, m2 | Weight, kg |

| PFPP | 592х287х360 | 8 | M5 | 1700 | 65 | 1,24 | 1,2 |

| 592х592х360 | 3400 | 65 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 55 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 55 | 4,26 | 2,2 | |||

| 592х287х360 | M6 | 1700 | 80 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 80 | 2,55 | 1,9 | |||

| 592х287х600 | 1700 | 70 | 2,0 | 1,3 | |||

| 592х592х600 | 3400 | 70 | 4,26 | 2,2 | |||

| 592х287х360 | F7 | 1700 | 125 | 1,24 | 1,2 | ||

| 592х592х360 | 3400 | 125 | 2,55 | 2,0 | |||

| 592х287х600 | 1700 | 90 | 2,0 | 1,35 | |||

| 592х592х600 | 3400 | 90 | 4,26 | 2,38 | |||

| 592х287х360 | F8 | 1700 | 170 | 1,24 | 1,25 | ||

| 592х592х360 | 3400 | 170 | 2,55 | 2,1 | |||

| 592х287х600 | 1700 | 110 | 2,0 | 1,4 | |||

| 592х592х600 | 3400 | 110 | 4,26 | 2,5 | |||

| 592х287х360 | F9 | 1700 | 220 | 1,24 | 1,28 | ||

| 592х592х360 | 3400 | 220 | 2,55 | 2,1 | |||

| 592х287х600 | 1700 | 160 | 2,0 | 1,45 | |||

| 592х592х600 | 3400 | 160 | 4,26 | 2,6 |

Pocket filters for fine cleaning made of microfine glass fiber

| Filter Type Code | Size (H x W x D), mm | Number of pockets, pcs. | Filtration class Interstate Standard R EN 779-2014 | Nominal capacity, m3/h | Initial pressure drop, Pa | Filter surface area, m2 | Weight, kg |

|---|---|---|---|---|---|---|---|

| PFGF | 490x592x600 | 5 | M5 | 2800 | 40-60 | 2,9 | 2,60 |

| 287x592x600 | 3 | 1700 | 1,1 | 2,20 | |||

| 592x287x600 | 6 | 2,2 | 2,20 | ||||

| 592x592x600 | 3400 | 5,7 | 2,80 | ||||

| 490x592x600 | 5 | M6 | 2800 | 70-90 | 2,9 | 2,60 | |

| 287x592x600 | 3 | 1700 | 1,1 | 2,20 | |||

| 592x287x600 | 6 | 2,2 | 2,20 | ||||

| 592x592x600 | 3400 | 5,7 | 2,80 | ||||

| 490x592x600 | 7 | F-7 | 2800 | 100-120 | 4,1 | 3,00 | |

| 287x592x600 | 4 | 1700 | 1,37 | 2,40 | |||

| 592x287x600 | 8 | 2,8 | 2,40 | ||||

| 592x592x600 | 3400 | 5,7 | 3,30 | ||||

| 490x592x600 | 7 | F-8 | 2800 | 120-140 | 4,1 | 3,00 | |

| 287x592x600 | 4 | 1700 | 1,37 | 2,40 | |||

| 592x287x600 | 8 | 2,8 | 2,40 | ||||

| 592x592x600 | 3400 | 5,7 | 3,30 | ||||

| 490x592x600 | 7 | F-9 | 2800 | 130-150 | 4,1 | 3,00 | |

| 287x592x600 | 4 | 1700 | 1,37 | 2,40 | |||

| 592x287x600 | 8 | 2,8 | 2,40 | ||||

| 592x592x600 | 3400 | 5,7 | 3,30 |

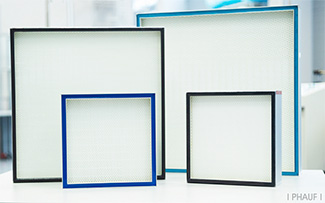

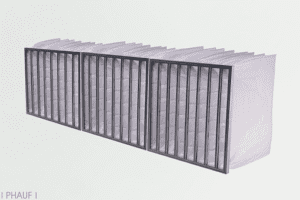

Pocket Filters – What They Are, Design Features

Ventilation pocket-type filters (VPF) are devices used for the 1st (first) and 2nd (second) stages of air purification in supply and exhaust units of ventilation systems in various premises.

Such filters are also used in air conditioning and heating systems of

buildings and structures.

Design of a Pocket Filter for Ventilation

The functional elements of the product are made of filter media, sewn (welded) in the form of several pockets. The number of pockets depends on the filter dimensions.

The larger the size and number of pockets, the greater the capacity and service life of the filter elements, and, consequently, the lower the resistance.

Used filter materials:

- for coarse pocket filters — volumetric fabrics made of 100% polyester (polyester fiber);

- for fine pocket filters — fibrous fabric material based on polypropylene (Meltblown technology).

The pockets of a fine filter can be additionally divided into separate compartments, separated by a separator. This segmentation ensures an even distribution of pollutant particles absorbed from the air across the plane of the filter media.

The filter element of the product is attached to a frame with crossbars. The latter give strength to the material tension. The number of crossbars on the frame corresponds to the number of filter pockets.

The product frame is made of galvanized steel in the form of a lock on rivet joints or from plastic.

The tightness of the filter element attachment to the profile is achieved through a foamed sealant laid around the perimeter of the frame.

Important! The maximum degree of VPF contamination is determined by reaching the final value of the pressure drop (measured by a differential pressure gauge).

The used filter is replaced with a new one — the product is not subject to cleaning, washing, or reuse.

Where are they used?

Pocket filters are used in medium and high-pressure ventilation units, suspended and floor-type supply units.

In single-stage supply units, VPF can be the only filtering element for cleaning outdoor air from insects, large dust, and dirt.

In multi-stage supply and exhaust ventilation systems of cleanrooms, these devices perform preliminary air treatment before it is supplied to the absolute HEPA filter.

Pocket filters (VPF) have found widespread use in filtration ventilation equipment of:

- residential premises;

- medical centers;

- shopping halls;

- industrial and utility rooms.

Classification of (VPF) by air purification level

The range of pocket-type filters of LLC «Research and Production Enterprise «MICROSYSTEM»» is produced in accordance with the requirements of updated versions of the international EN 779:2012 and national Interstate Standard R EN 779-2014 standards and includes groups of products:

- coarse air purification — filtration classes G3, G4);

- intermediate or medium air purification — filtration classes M5 (F5), M6 (F6);

- fine air purification — filtration classes F7, F8, F9.

Coarse filters G3, G4. Technical characteristics

Air pocket filters of 1st stage filtration carry out preliminary (basic) treatment of supply and circular air in residential or industrial premises. They also protect parts of the ventilation units themselves from contamination:

- fan units;

- heat exchangers of heaters and coolers;

- adiabatic air humidification sections;

- heat recovery sections.

Medium and fine air filters M5/F5, M6/F6, F7, F8, F9. Technical characteristics

Important!

According to the current Interstate Standard R EN 779–2014, fine filter classes F5 and F6 have been replaced by medium filter classes M5 and M6 while maintaining the same characteristics.

The task of 2nd stage air pocket filters is to ensure specified hygienic parameters of air purity inside buildings.

Fine filtration VPFs can retain atmospheric pollutants smaller than 1 μm, including allergens and bacteria (class F9). They are suitable for sufficient and effective air purification in residential, office, medical, and similar premises.

They are also used as pre-filters for high-efficiency HEPA filters in multi-stage supply and exhaust ventilation systems of cleanrooms and sterile zones.

Advantages of air pocket filters

The advantages of air filters include:

- simple design;

- low resistance;

- high dust holding capacity;

- reliability, durability;

- easy replaceability;

- progressive filter materials (microbiologically inactive, self-extinguishing);

- disposable as solid construction waste;

- low price.

How to choose an air pocket filter?

To order and buy a pocket filter for ventilation, it’s important to determine its shape, dimensions, technical characteristics, and required filtration class.

This information is specified in the technical passport of the corresponding ventilation unit, in the design documentation of the corresponding filtration ventilation equipment, or on the information plate of the «old» (to be replaced) filter.

Specialists of our company develop and produce filters of any design according to individual customer orders.

What should you pay attention to when ordering VPF?

- Frame material – preferably: rolled profile of galvanized steel. In some cases, high-quality plastic is acceptable.

- Pocket material – modern synthetic filter material (polyester, polypropylene Meltblown), non-toxic, heat-resistant, multi-layer structure, glued with thermal adhesive.

- Ensuring complete tightness of all structural element connections.

- For external air intakes, it’s better to choose coarse filters of classes G3, G4.

All products of LLC «Research and Production Enterprise

«MICROSYSTEM»» comply with Interstate Standards, Technical Specifications, and fire safety requirements.

Each product is provided with a passport and a quality certificate.

Marking of pocket filters

1 Type:

- PFPE – pocket filter with polyester filter media;

- PFPP – pocket filter with polypropylene filter media;

- PFGF – pocket filter with microfine glass fiber filter media.

2 Construction:

- GAL – frame made of galvanized steel;

- PLA – frame made of plastic.

3 Frame thickness (mm):

- 25.

4 Filtration class according to Interstate Standard R EN 779-2014:

- G3;

- G4;

- M5;

- M6;

- F7;

- F8;

- F9.

5 Number of pockets, pcs:

- from 3 to 10.

6 Filter dimensions:

- W – filter width (from 287 to 892 mm);

- H – filter height (from 287 to 892 mm);

- D – pocket depth (from 100 to 1000 mm).

7 Presence of sealant:

- NV – continuous sealant on the air flow inlet side;

- NP – continuous sealant on the air flow outlet side;

- ND – continuous sealant on both sides.

Notes to point 1:

- PE – filter media made of polyester; *PP – filter media made of polypropylene (meltblown); *GF – filter media made of microfine glass fiber.

Marking example:

- PFPP – GAL – 25 / F7 – 8 / 592 х 592 х 360 / NP.

Important!

Our production facility manufactures standard and non-standard filters of various sizes, with different numbers of pockets – according to the customer’s wishes.

Pocket Filters – What Are They, Design Features

Pocket-type ventilation filters (PVF) are devices used for the 1st (first) and 2nd (second) stages of air purification in supply and exhaust systems of various premises’ ventilation systems.

Such filters are also used in air conditioning and heating systems for buildings and structures.

Design of a Pocket Filter for Ventilation

The functional elements of the product are made from filter media, sewn (or welded) in the form of several pockets. The number of pockets depends on the filter’s dimensions.

The larger the size and number of pockets, the greater the capacity and service life of the filter elements, and, consequently, the lower the pressure drop.

Filter media used:

- for coarse pocket filters – volumetric fabrics made of 100% polyester (polyester fiber);

- for fine pocket filters – fibrous fabric material based on polypropylene (Meltblown technology).

The pockets of fine filters can be additionally divided into separate compartments, separated by a separator. This segmentation ensures even distribution of air pollutants absorbed across the plane of the filter media.

The filter element is attached to a frame with cross bars. These provide strength to the material tension. The number of bars on the frame corresponds to the number of filter pockets.

The product frame is made of galvanized steel in the form of a lock with rivet joints or plastic.

The airtight attachment of the filter element to the profile is achieved through a foam sealant laid around the frame perimeter.

Important! The maximum degree of PVF contamination is determined by reaching the final pressure drop value (measured with a differential pressure gauge).

A used filter is replaced with a new one – the product is not subject to cleaning, washing, or reuse.

Where Are They Used?

Pocket filters are used in medium and high-pressure ventilation units, as well as suspended and floor-type supply units.

In single-stage supply units, PVFs can be the only filtering element for cleaning outdoor air from insects, coarse dust, and dirt.

In multi-stage supply and exhaust ventilation systems for cleanrooms, these devices perform preliminary air treatment before it is supplied to the absolute HEPA filter.

Pocket filters (PVF) have found widespread use in filtration ventilation equipment for:

- residential premises.

- medical centers;

- shopping halls;

- industrial and utility rooms.

Classification of Pocket-Type Ventilation Filters (PVF) by Air Purification Level

The range of pocket-type filters produced by LLC «Research and Production Enterprise «MICROSYSTEM»» is manufactured in accordance with the requirements of updated versions of the international EN 779:2012 and national Interstate Standard R EN 779-2014 standards, and includes the following product groups:

- coarse air filtration – filtration classes G3, G4;

- intermediate or medium air filtration – filtration classes M5 (F5), M6 (F6);

- fine air filtration – filtration.

Coarse Filters G3, G4

Technical Specifications

First-stage pocket air filters perform preliminary (basic) treatment of supply and recirculated air in residential or industrial premises. They also protect parts of the ventilation units themselves from contamination:

- dan units;

- heat exchangers of heaters and coolers;

- adiabatic air humidification sections;

- heat recovery sections.

Technical Specifications of Coarse PVF

| Filter Characteristic | Description |

| Product Type | Pocket filter for ventilation |

| Group | Coarse filters |

| Filtration classes according to EN 779:2012 | G3, G4 |

| Average efficiency for particles 0.4 μm | less than 40% |

| Average dust holding capacity (particles larger than 10 μm) Am, % | G3 80≤Am<90<br>G4 90≤Am |

| Initial pressure drop | 30 Pa |

| Final pressure drop (recommended pressure differential) | 250 Pa |

| Operating temperature range | From -60°C to +80°C |

| Fire safety class (according to DIN 53438) | F1 |

| Filter media | Polyester |

Medium and Fine Air Filters M5/F5, M6/F6, F7, F8, F9.

Technical Specifications

Important!

According to the current Interstate Standard R EN 779-2014, fine filter classes F5 and F6 have been replaced by medium filter classes M5 and M6 while retaining their previous characteristics.

The task of second-stage pocket air filters is to ensure specified hygienic parameters of air purity inside buildings.

Fine filtration PVFs can retain atmospheric pollutants smaller than 1 micron, including allergens and bacteria (class F9). They are suitable for sufficient and effective air purification in residential, office, medical, and similar premises.

They are also used as pre-filters for high-efficiency HEPA filters in multi-stage supply and exhaust ventilation systems for cleanrooms and sterile zones.

Technical Specifications of Second-Stage PVF

| Characteristic according to EN 779:2012 | Medium filtration pocket filters | Fine filtration pocket filters |

| Minimum efficiency for particles 0.4 μm | less than 40% | 35-55-70% |

| Initial pressure drop | from 70 Pa | from 70 Pa |

| Final pressure drop | 450 Pa | 450 Pa |

| Operating temperature range | from -60°C to +80°C | from -60°C to +80°C |

| Fire safety class (according to DIN 53438) | F1 | F1 |

| Filter media | Multilayer progressive Meltblown | Multilayer progressive Meltblown |

Designation PFPP – GAL – 25 / F7 – 8 / W x H x D / NP of filters — decoding

The product passport and the information plate on the filter, located on the outer side of the frame profile, indicate the manufacturer’s information, overall dimensions, filtration class, and air flow capacity of the filter.

Advantages of Pocket Air Filters

- Simple design.

- Low pressure drop.

- High dust holding capacity.

- Functionally reliable, durable.

- Easy to replace.

- Progressive filter media (microbiologically inactive, self-extinguishing).

- Disposed of as solid construction waste.

- Low price.

How to Choose a Pocket Air Filter

To order and buy a pocket filter for ventilation, it’s important to determine its shape, dimensions, technical specifications, and required filtration class.

This information is specified in the technical passport of the corresponding ventilation unit, in the design documentation of the corresponding filtration ventilation equipment, or on the information plate of the «old» (to be replaced) filter.

Specialists of our company develop and produce filters of any design according to individual customer orders.

What should you pay attention to when ordering PVF?

- Frame material – preferably: rolled profile made of galvanized steel. In some cases, high-quality plastic is acceptable.

- Pocket material – modern synthetic filter media (polyester, polypropylene Meltblown), non-toxic, heat-resistant, multi-layered structure, bonded with thermal adhesive.

- Ensuring complete airtightness of all structural element connections.

- For external air intakes, it’s better to choose coarse filters of classes G3, G4.

All products of LLC «Research and Production Enterprise «MICROSYSTEM»» comply with Interstate Standards, Technical Specifications, and fire safety requirements.

Each product comes with a passport and quality certificate.