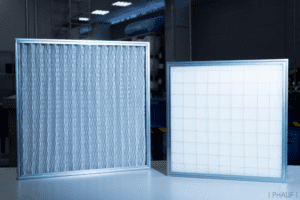

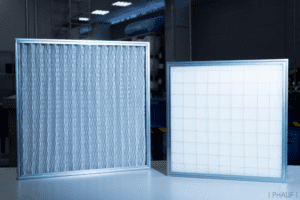

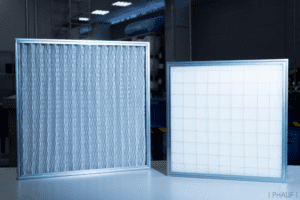

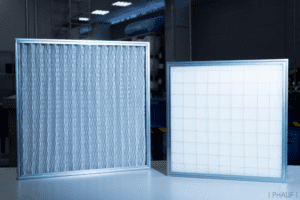

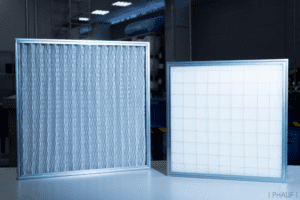

Panel filters (FPT Series)

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 25 | 25 | 48 | 48 |

| Filter surface area, m² |

0.17 | 0.35 | 0.17 | 0.35 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 25 | 25 | 48 | 48 |

| Filter surface area, m² |

0.17 | 0.35 | 0.17 | 0.35 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 25 | 25 | 48 | 48 |

| Filter surface area, m² |

0.17 | 0.35 | 0.17 | 0.35 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 287 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 25 | 25 | 48 | 48 |

| Filter surface area, m² |

0.17 | 0.35 | 0.17 | 0.35 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

| Width, mm | 287 | 592 | 287 | 592 |

| Height, mm | 592 | 592 | 592 | 592 |

| Depth, mm | 25 | 25 | 48 | 48 |

| Filter surface area, m² |

0.17 | 0.35 | 0.17 | 0.35 |

| Nominal capacity, m³/h |

1700 | 3400 | 1700 | 3400 |

ORDER FORM

INFORMATION

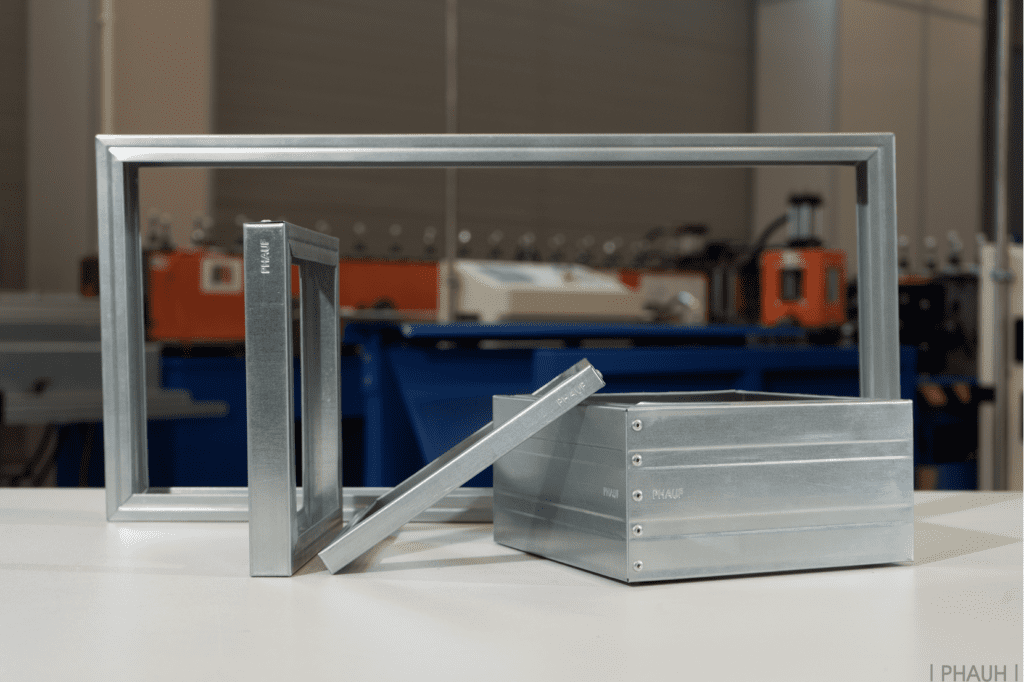

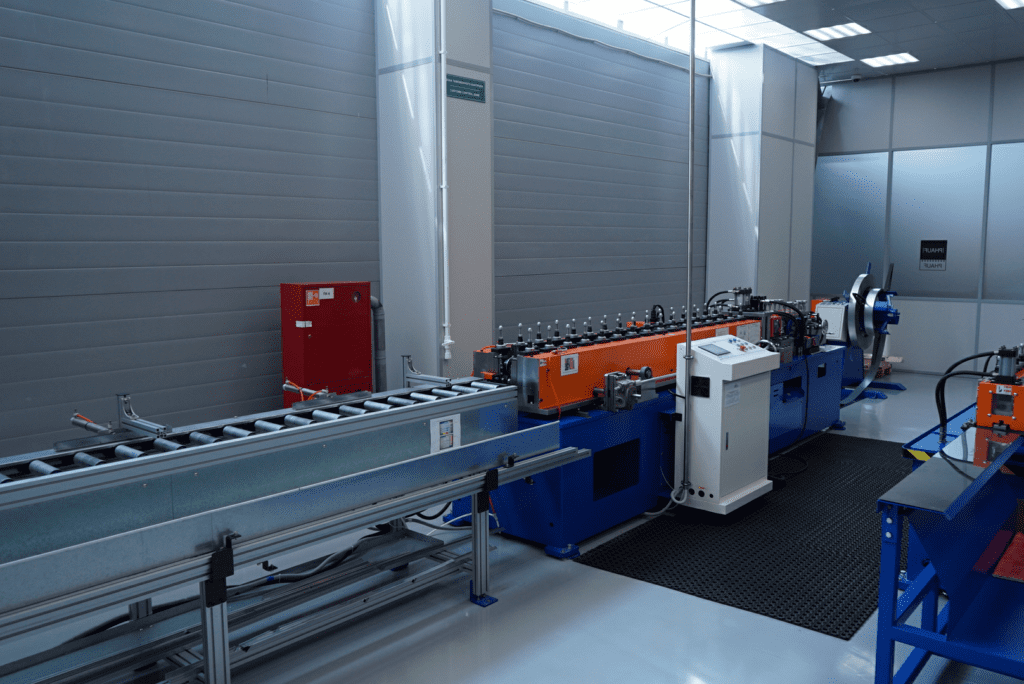

The filter frame is manufactured from galvanized profile (standard profile depths are 25, 48, 96, 100 mm) on an automated forming line without human intervention, with the ability to change the frame depth from 20 to 100 mm, and has a special design to enhance the rigidity of the filter frame.

The filter media is made of chemical fiber or glass fiber with filtration classes from G2 to M5, with supporting welded grids of 50×50 mm cell size made of galvanized or composite wire.

Panel-type filter with polyester media

| Frame material / code | Size (H x W x D), mm | Filtration Class Interstate Standard R EN 779-2014 | Nominal Air Flow, m3/h | Initial Pressure Drop, Pa | Filter Surface Area, m2 | Weight, kg |

| 1) Galvanized frame / FGPE 2) Plastic frame / FPPE 3) Stainless steel frame / FSPE |

592х287х25 | G3 | 1700 | 80 | 0,17 | 0,6 |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 | |||

| 592х287х25 | G4 | 1700 | 100 | 0,17 | 0,6 | |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 | |||

| 592х287х25 | M5 | 1700 | 120 | 0,17 | 0,6 | |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 |

Panel-type filter with glass fiber media

| Frame material / code | Size (H x W x D), mm | Filtration Class Interstate Standard R EN 779-2014 | Nominal Air Flow, m3/h | Initial Pressure Drop, Pa | Filter Surface Area, m2 | Weight, kg |

| 1) Galvanized frame / FGGF 2) Plastic frame / FPGF 3) Stainless steel frame / FSGF |

592х287х25 | G3 | 1700 | 70 | 0,17 | 0,6 |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 | |||

| 592х287х25 | G4 | 1700 | 85 | 0,17 | 0,6 | |

| 592х592х25 | 3400 | 0,35 | 1,0 | |||

| 592х287х48 | 1700 | 0,17 | 0,8 | |||

| 592х592х48 | 3400 | 0,35 | 1,4 |

- Operating temperature range: from -40°C to +80°C

- Fire safety class (according to DIN 53438): F1

- Filter pack thickness (filter depth, frame profile thickness) depends on the chosen dimensions of the specific product: 15 mm, 25 mm, 48 mm, 96 mm, 100 mm

Technical characteristics of a particular panel filter may slightly differ depending on its modification and manufacturer, for example:

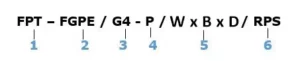

Marking example:

- FPT – FGPE / G4 -400 / 592 x 592 x 48 / RD;

- FKT – FGGF / G3 -200 / 592 x 592 x 48 / RD.

FVP filter designation – decoding

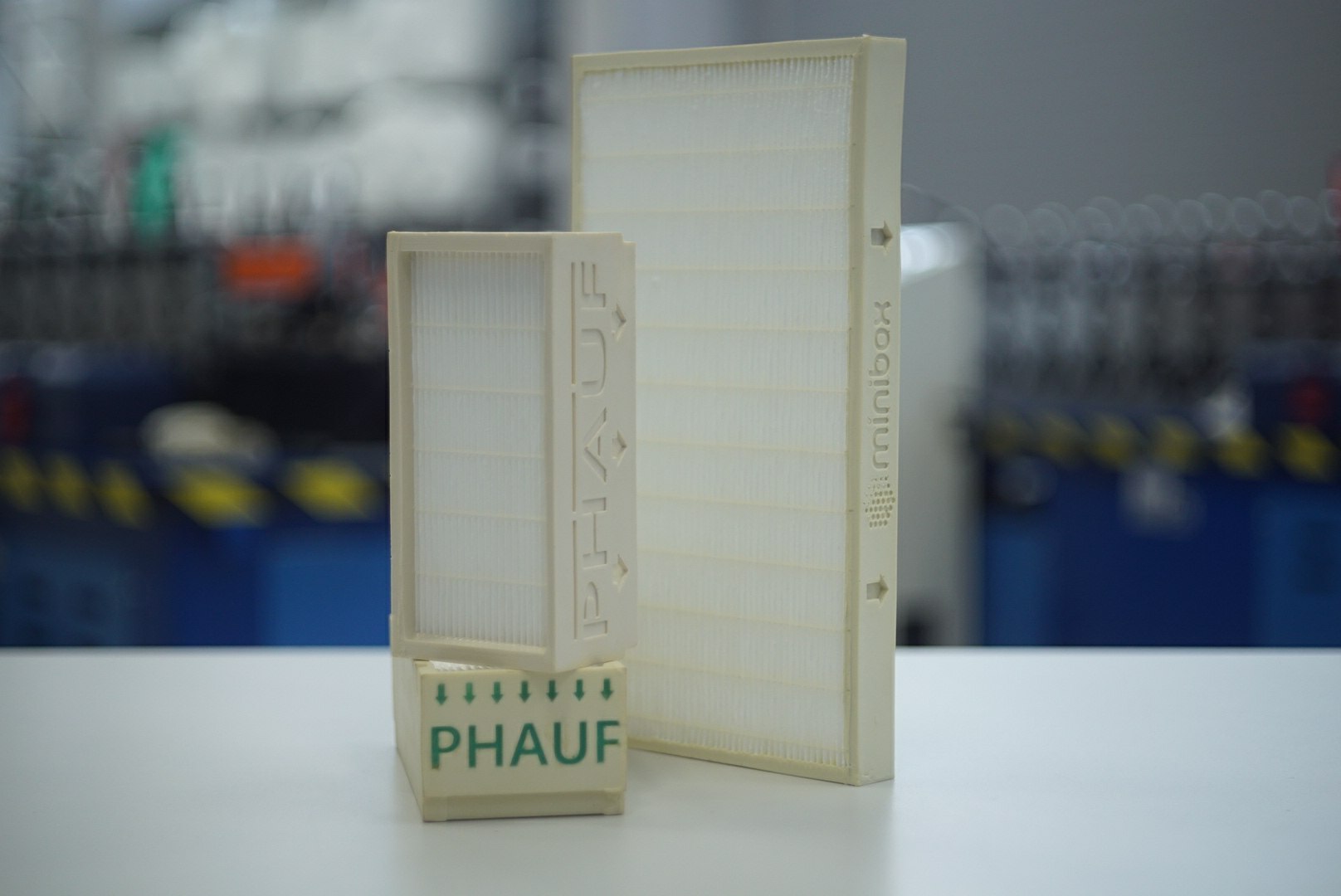

The packaging box and the outer side of the filter case bear a marking with the product’s conventional designation.

1 Type:

- FPT – Panel-type filter.

2 Frame material, type of filter media:

- FGPE – galvanized frame with polyester filter media;

- FPPE – plastic frame with polyester filter media;

- FSPE – stainless steel frame with polyester filter media;

- FGGF – galvanized frame with glass fiber filter media;

- FPGF – plastic frame with glass fiber filter media;

- FSGF – stainless steel frame with glass fiber filter media.

3 Filtration class according to Interstate Standard R EN 779-2014:

- G3;

- G4;

- М5.

4 Density of filter media:

- for polyester P = 150, 200, 250, 400 g/m2;

- for glass fiber P = 200, 250, 300 g/m2.

5 Filter dimensions:

- W – filter width – dimension of the smaller side of the filter, mm (min 100 max 1000 mm);

- H – filter height – dimension of the larger side of the filter, mm

(min 100 max 1000 mm); - D – filter depth (min 15 max 100 mm, standard sizes: 20; 25; 48; 96; 100 mm).

6 Filter media fixation:

- RPS – grid on the air outlet side, spokes on the air inlet side;

- RD – grid on both sides.

Marking example:

FPT – FGPE / G4 – 400 / 592 x 592 x 48 / RPS.

Important!

Our company LLC «Research and Production Enterprise «MICROSYSTEM»» produces standard and non-standard ventilation filters of various designs and any overall dimensions according to the customer’s order.

Where and why are PAFs used for supply ventilation systems

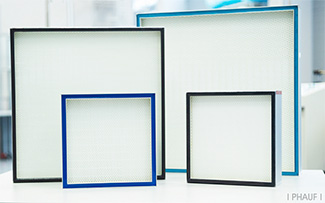

Panel-type air filter (PAF) – a diverse line of products for the 1st (first) stage of purification of supply (less often – exhaust) air.

Due to the simplicity and reliability of their design, safe installation and dismantling, and ability to withstand high mechanical and temperature loads, PAF air filters are used in ventilation systems of premises for any purpose: domestic, utility, industrial, and others.

Tasks of panel filters for ventilation:

- preliminary air cleaning (as part of its preparation for supply to fine filters) in multi-stage filtration ventilation systems of buildings and premises;

- basic (single-stage) air cleaning of domestic and industrial premises with low requirements for the cleanliness level of the surrounding space;

- air cleaning in specialized industrial premises, for example, chemical laboratories, paint booths, etc.;

- protection from dust, sand, abrasives, large aerosol particles and other macro-pollutants of air ducts, functional units of ventilation, heating and air conditioning systems.

Design of Air Panel Filters

As a filter media for panel ventilation filters of the first stage of purification, a volumetric non-woven fabric is used:

- high-quality chemical fiber (100% polyester, 100% polyester FilTek, PU foam);

- glass fiber.

The filter element of the product is represented by a cut of filter cloth laid on a support welded grid made of reinforced or galvanized steel rods.

The frame grid ensures reliable fastening of the filter material in the product frame and increases its service life.

On the air flow inlet side, the filter cloth is secured by steel diagonal rods (spokes) or a second frame grid.

The filter case is represented by a rigid frame made of galvanized steel, stainless steel, fastened with a lock by means of rivet joints or a plastic frame fastened with rivets.

The overall dimensions (H x W x D) of the frame profile can be standard or determined by the initial data of an individual customer who wishes to buy a non-standard PAF filter.

All filters for ventilation equipment produced by LLC «Research and Production Enterprise «MICROSYSTEM»» meet the requirements of national industry standards.

Filtration Classes

Panel-type filters are designed for coarse (less often – medium) purification of supplied air.

Our company produces PAF of the following filtration classes (according to Interstate Standard R EN 779-2007):

- G3;

- G4;

- М5.

Types of Ventilation Panel Filters

The demand and versatility of panel-type filters imply many modifications.

Different product brands differ from each other:

- by type of filter media;

- by purpose (for example, filters are produced for round and rectangular duct sections);

- by the method of fixing the filter cloth in the frame profile.

In ventilation and air conditioning systems, panel filters of the following frame structures are usually used:

- steel spokes at the inlet and support grid at the outlet of the air flow;

- frame grid on both sides of the filter material.

Technical Characteristics of PAF

- initial pressure drop (depending on the product brand): from 30 to 90 Pa;

- final pressure drop (depending on the product brand): from 130 to 250 Pa;

- initial dust content of supplied air: up to 3 mg/m3;

- operation at relative air humidity: up to 100%.

Advantages of Panel Filters

The main advantages of panel filters include:

- light and durable construction;

- simple and safe installation;

- high dust holding capacity;

- low initial pressure drop;

- possibility of filter regeneration by replacing the filter media (when the final pressure drop is reached, the contaminated cloth is removed from the frame and replaced with a new one);

- used filter cloth is disposed of as ordinary solid construction waste;

- fire safety (materials do not support fire combustion);

- environmental safety;

- low product price.

An important advantage of PAF filters is the combination of their low cost with reusable resource.

Air Panel Filter PAF

The air panel filter (PAF) is designed for preliminary air purification in ventilation systems and paint booths. It is an essential element of ventilation systems, providing reliable protection against dust particles, fibers, paint, aerosols, etc. Its advantages include:

- even distribution of dirt fractions;

- reliable attachment to the frame;

- low initial resistance;

- reliable protection: captures particles larger than 10 μm.

Where PAF Filters Are Used

Panel filters are used for coarse preliminary air purification and are installed as the first working unit after the damper before the fan. In a single-stage ventilation system, it can act as the main air purification filter.

Panel-type filters have a wide range of applications. They are used both in premises with low requirements for supply air purity (schools, offices, warehouses, shopping centers, etc.) and in chemical/pharmaceutical laboratories, paint booths, etc.

Construction of Panel Filter FTP

The PHAUF panel filter consists of:

- profile made of galvanized iron, stainless steel, or plastic;

- filter media made of polyester/glass fiber of filtration class (G3-M5);

- support welded grid made of galvanized wire.

There are two types of constructions. The first with a grid at the inlet and outlet. The second — with steel spokes at the inlet and a grid at the outlet.

The price of panel filters will depend on the size and filter layer. Thus, the higher the filtration capabilities of the material, the more expensive the panel filter. Want to know the exact price? Contact us through the feedback form or by phone: +7 (495) 108-43-97.

PAF Dimensions

Having our own production allows our company to manufacture filters of any design and modification. Contact us in any convenient way, and we will provide free technical consultation on all your questions.

The width of the profile into which the filter material is laid is usually 25, 48, 96, 100 mm. However, at your request, specialists of LLC «Research and Production Enterprise «MICROSYSTEM»» will develop a filter of any filtration class, size, and design.

Filtration Classes

Depending on the efficiency of filtration capacity, there are three filtration classes: coarse, fine, and ultra-high efficiency (ULPA).

Coarse panel filters (G1, G2, G3, G4) can capture particles larger than 10 μm. These include:

- large dust particles;

- insects;

- plant seeds;

- feathers and down;

- soot.

Special Features of PAF Panel Filters

A distinctive feature of the panel type is that the filtration coefficient increases as various contaminants accumulate. This occurs due to the narrowing of the gaps between fibers. However, it’s important to remember that over time, these gaps will narrow to such an extent that the filter media will cease to provide the necessary flow capacity and will need to be replaced.

Methods for Monitoring the Degree of PAF Contamination

Panel filters are responsible for creating an optimal and safe microclimate in premises of various purposes. Timely monitoring of the contamination level prevents accelerated equipment wear and reduces the frequency of filter replacement.

Methods for monitoring filter contamination:

| Monitoring Method | Description |

| Visual | This method involves periodic inspection of the filter layer for contamination. |

| Automated | This is a more accurate method of contamination control. Notifications for filter replacement come from gas sensors, counters, and pressure gauges. |

Requirements for Replacement Periods

Ventilation performance directly depends on the degree of filter contamination. To avoid damage to equipment and interior finishes, it’s necessary to strictly follow the manufacturer’s recommendations for replacement intervals.

Factors that affect the rate of contamination include:

- building height;

- seasonality and climatic features;

- presence of growing trees and pollen nearby;

- overall gas contamination level.

A layer of dust and grease significantly reduces the flow capacity of the filter layer. Additionally, disassembly and cleaning of ventilation units will take considerable time and effort. We recommend not violating the regulated terms: replace once a month in summer, once every 2-3 months in winter.